Same or Reversed Wiring Harnesses?

There are two common ways to assemble wiring harnesses, of which appear to go by several sets of names. Most notable pairs are: "same" vs "reversed", otherwise known as "socket to socket" vs "socket to socket reversed", as well as, 1:1 vs 1:N styles.

Regardless of the naming scheme used, it is sometimes difficult to determine what exact configuration the cable assembly is in. Some care should be taken when this information is not directly given.

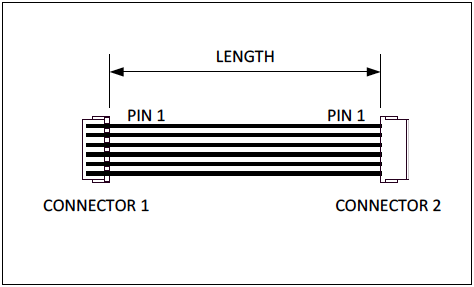

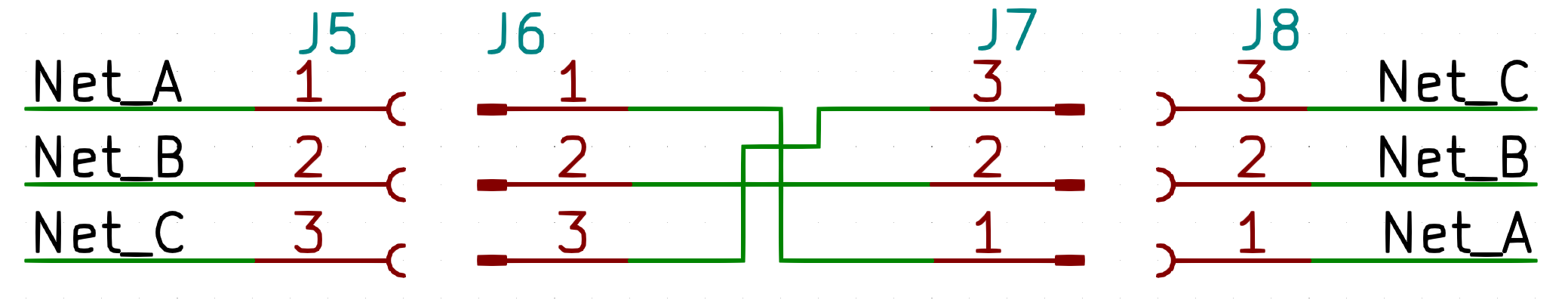

Reversed, Socket-Socket Reversed

- Mating connectors match.

- Intuitive schematic documentation.

- When connected, the wires will cross over one another. Leading to more stress.

- Slightly, less intuitive wiring process.

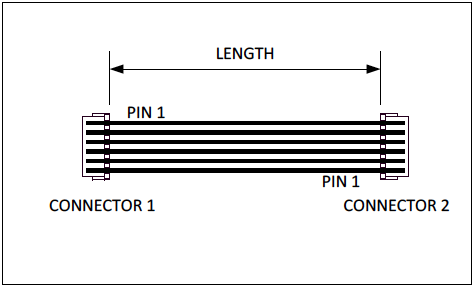

Same, Socket-Socket

- Intuitive cable assembly.

- When connected, the wires lay flat and straight. As one conductor leads directly to the other.

- Schematic is not intuitive. Would not match datasheet of mating device.

According to Digikey's current inventory, the stock of Socket-Socket is 329 while Socket-Socket Reversed is 356. Based on this it's hard to come to a conclusion as to which is more prevalent.

All in all, choosing the cable style is essentially an arbitrary choice. Each has a trade off of absorbing the drawback, either the cable or the PCB has to own the conductor reversal. This can be determined based the stage of the project and application. For example, if the PCBs have already been made and tested then there is no choice but to have the cable own it.

PS: Keep in mind of services like Dirty Cables exist for making custom wiring harnesses in those cases where a custom harness is needed. My other goto is excellence electronic from Aliexpress, as they have a great selection of prebuilt JST-like connectors in many sizes and configurations.

Connector images courtesy of JST's Harness Maker Form.